REAL ACTIONS TO ENSURE FOOD SECURITY

FAO: «States should take appropriate emergency preparedness measures, such as keeping food stocks for the acquisition of food, and take steps to put in place adequate systems for distribution». — FAO, 2003

ASEAN is committed to encourage each ASEAN Member State to strengthen its own Local Resource-based Food Reserve dedicated to Emergency Preparedness and Response on food security and nutrition in response to crises in the region. — ASEAN, 2023

IAEA: «Food irradiation is an innovative, gentle, and non-invasive technique that uses radiation to keep food fresh and safe to eat». — IAEA, 2025

Advantages of Processing Food Products with Ionizing Radiation

Eliminates insects, their larvae and pathogenic microorganisms

Extends shelf life of treated products

Preserves the natural structure and organoleptic properties of the treated products

Leaves no residual radiation — the product remains completely safe

Allows processing in any sealed packaging, preventing recontamination

Environmentally friendly and energy-efficient treatment method

The shelf life of processed products depends on the following factors:

1) The level of contamination of food products with pathogens, insects and their larvae before the process of ionizing radiation treatment.

2) The characteristics of the packaging material (materials and packages that prevent the ingress of insects and pathogenic microorganisms, as well as materials with an oxygen barrier provide the longest shelf life).

3) The level of sterility of the storage facilities in which the products will be stored after their radiation treatment.

4) Temperature conditions and humidity in the storage facilities.

FAO and IAEA have developed a joint Atoms4Food Initiative to support food security programmes

IAEA ON IONIZING RADIATION SAFETY

Atoms4Food Initiative objectives:

- Help eliminate hunger, food insecurity and malnutrition

- Make agriculture, forestry and fisheries more productive and sustainable

- Reduce rural poverty

- Enable inclusive and efficient agricultural and food systems

- Increase the resilience of livelihoods to threats and crises

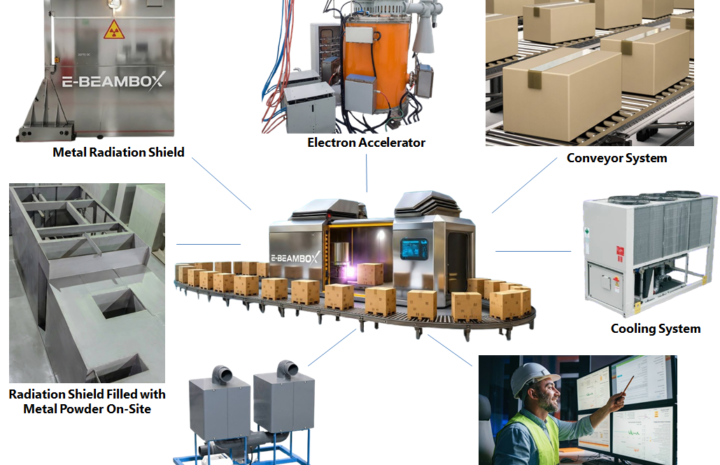

Within the framework of its Atoms for Food Equipment programme, Beamcomplex manufactures and constructs compact boxes – E-Beambox – with electron accelerators to place them in existing food long-term storage warehouses to process products with ionizing radiation (E-beam/X-Ray).

BENEFITS OF E-BEAMBOX

E-Beambox is a prefabricated container-type system, ready for quick installation and commissioning. The complex consists of four modules assembled at the plant that include:

— electron accelerator;

— conveyor systems;

— electron accelerator cooling system;

— electronic unit of the accelerator;

— systems of ozone extraction, radiation background control, automatic shutdown of the accelerator, fire extinguishing and other systems.

USING THE E-BEAMBOX FOR E-BEAM AND X-RAY PRODUCT PROCESSING REDUCES FACILITY COMMISSIONING TIME AND LOWERS COSTS COMPARED TO COSTS FOR CONSTRUCTING AND INSTALLING OF SEPARATE SYSTEMS.

Get personalized offer

BENEFITS OF HAVING NATIONAL FOOD STOCKS WITH LONG SHELF LIFE FOOD PRODUCTS FOR COUNTRIES

Total independence of a country in case of disruption of food supply chains during emergencies (pandemic, military conflicts, natural and man-made disasters).

Reduction of food losses and waste due to extension of food shelf life with the help of ionizing radiation tehcnology.

Increase in replenishment periods and reduction of budget expenses due to the supply of extended shelf life food to national food stocks.

Reduction of intestinal diseases in the population of a country.

Prevention of social upheavals, support of sustainable economic development and food security enhancement.

Achievement of Zero Hunger goal.

STAGES OF MANUFACTURE OF E-BEAMBOX AND ITS PLACEMENT AT THE WAREHOUSE

Shipment of Module to the Customer

Shipment of Module to the Customer Placement of E-Beambox on Customer's Site

Placement of E-Beambox on Customer's Site  Filling of Module No. 1 of E-Beambox with Concrete Radiation Shield

Filling of Module No. 1 of E-Beambox with Concrete Radiation Shield Putting the Box into Operation

Putting the Box into OperationSHELF LIFE OF PRODUCTS TREATED WITH IONIZING RADIATION

*The long shelf life is due to the fact that the products are exposed to the maximum permissible dose of radiation, as well as the use of packaging materials that are insect-, moisture- and oxygen-proof.

| Types of Food Products | Irradiation Dose (kGy) | Mode | Shelf Life Extension |

|---|---|---|---|

| 1) Cereals (rice, semolina, buckwheat, etc.) | 1 | E-beam/X-Ray | Up to to 5 years, *Up to 10 years |

| 2) Grains (wheat, rice, etc.) | 0.2-0.5 | E-beam | Up to 1 year |

| 3) Flour | 4 | E-beam/X-Ray | Up to to 5 years, *Up to 10 years |

| 4) Noodle products | 4 | E-beam/X-Ray | Up to to 5 years, *Up to 10 years |

| 5) Frozen chicken meat, poultry (fowl, geese, ducks, guinea fowls, pigeons, quails, and turkeys) | 7 | E-beam/X-Ray | Up to 1 year, *Up to 3 years |

| 6) Chilled chicken meat, poultry (fowl, geese, ducks, guinea fowls, pigeons, quails, and turkeys) | 7 | E-beam/X-Ray | Up to 1 year, *Up to 2 years |

| 7) Chilled chicken fillet, minced chicken | 7 | E-beam/X-Ray | Up to 1 year, *Up to 2 years |

| 8) Chilled fish and shellfish (incl. eels, crustaceans and mollusks) | 3 | E-beam/X-Ray | Up to 1 year, *Up to 2 years |

| 9) Frozen peeled or decapitated shrimps | 5 | E-beam/X-Ray | Up to 1 year, *Up to 3 years |

| 10) Chilled shrimps | 3 | E-beam/X-Ray | Up to 1 year, *Up to 2 years |

| 11) Frozen frog legs | 5 | E-beam/X-Ray | Up to 1 year, *Up to 3 years |

| 12) Lean pork (minced) | 0.3-1 | E-beam/X-Ray | Up to 1 year, *Up to 2 years |

| 13) Raw chilled meat | 4.5 | E-beam/X-Ray | Up to 1 year, *Up to 2 years |

| 14) Frozen beef | 7 | E-beam/X-Ray | Up to 1 year, *Up to 3 years |

| 15) Chicken eggs | 7 | E-beam | Up to 2 months, *Up to 5 months |

| 16) Dried vegetables and fruits | 1 | E-beam/X-Ray | Up to 2 years, *Up to 4 years |

| 17) Potatoes | 0.1-0.2 | E-beam | Up to 1 year |

| 18) Yams | 0.2 | E-beam | Up to 1 year |

| 19) Onions | 0.06-0.2 | X-Ray | Up to 1 year |

| 20) Garlic | 0.075-0.2 | X-Ray | Up to 1 year |

| 21) Shallots | 0.075-0.2 | X-Ray | Up to 1 year |

| 22) Vegetables | 1 | E-beam/X-Ray | Up to 1 year |

| 23) Fruit (incl. tomato, rhubarb) | 0.15-0.6 | X-Ray | Up to 3 months, *Up to 6 months |

| 24) Berries | 0.15-0.6 | X-Ray | Up to 2 months, *Up to 4 months |

| 25) Casein, caseinates | 6 | E-beam/X-Ray | Up to 1 year, *Up to 10 years |

| 26) Animal feed (compound feed) | 5 | E-beam/X-Ray | Up to 1 year, *Up to 2 years |

| 27) Pet food | 25 | E-beam/X-Ray | Up to 1 year, *Up to 5 years |

| 28) Tea, coffee, cocoa | 1-14 | E-beam/X-Ray | Up to 3 years, *Up to 10 years |

| 29) Deep frozen aromatic herbs | 10 | E-beam/X-Ray | Up to 3 years, *Up to 5 years |

Request technical quotation

ATOMS FOR FOOD EQUIPMENT – HALAL

Ionizing radiation food preservation technology for Halal food products

With the Muslim population estimated at 1.9 billion people globally, the demand for halal-certified products is massive. Halal Certification stands out as a critical standard that governs the production and distribution of foods for millions of Muslims worldwide.

With the Muslim population estimated at 1.9 billion people globally, the demand for halal-certified products is massive. Halal Certification stands out as a critical standard that governs the production and distribution of foods for millions of Muslims worldwide.

Countries like Malaysia, Indonesia, Saudi Arabia, and the United Arab Emirates have strict import regulations requiring Halal Certification for food products, ensuring that the goods comply with religious guidelines. For companies wanting to export to these countries, obtaining Halal Certification is non-negotiable. – Halal Food Council USA.

At the same time, countries with strict Halal control experience such food challenges as food losses, food contamination with insects and pests and others. In this regard Islamic organizations (e.g. Social Sciences University of Ankara Institute of Islamic Studies) suggest reducing food waste by adopting environmentally friendly strategies. Ionizing radiation technology has proved its sustainability (as only grid electricity is used) and has been applied to secure food safety without introducing Haram substances in many countries practicing Halal. Please refer to regulatory documents below.

IOFS MISSION

The mission of the Islamic Organization for Food Security (IOFS) is deeply rooted in the commitment to guaranteeing sustainable food security across the Organization of Islamic Cooperation (OIC) Member States. This pivotal mission is achieved through a multifaceted approach encompassing socio-economic development and the systematic promotion of targeted programs in key areas such as agriculture, science and technology, humanitarian aid, and food trade. IOFS stands as a beacon for collaboration, working tirelessly within the OIC Member States to create a robust framework that not only addresses immediate food security concerns but also cultivates long-term resilience and prosperity through innovative initiatives and strategic partnerships.

The mission of the Islamic Organization for Food Security (IOFS) is deeply rooted in the commitment to guaranteeing sustainable food security across the Organization of Islamic Cooperation (OIC) Member States. This pivotal mission is achieved through a multifaceted approach encompassing socio-economic development and the systematic promotion of targeted programs in key areas such as agriculture, science and technology, humanitarian aid, and food trade. IOFS stands as a beacon for collaboration, working tirelessly within the OIC Member States to create a robust framework that not only addresses immediate food security concerns but also cultivates long-term resilience and prosperity through innovative initiatives and strategic partnerships.

RELATED RESOURCES

FAO NEWS

Afghanistan: FAO and UK launch GBP 10 million initiative to boost rural resilience and food securityRead more

Afghanistan: FAO and UK launch GBP 10 million initiative to boost rural resilience and food securityRead moreWe are ready to answer all your questions!