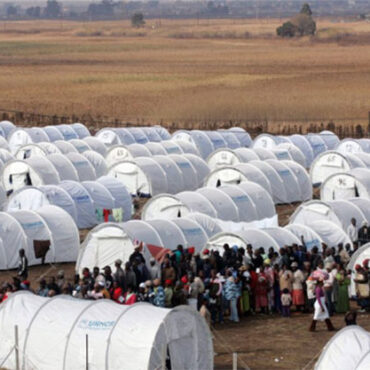

The technology for processing food products using ionizing radiation (E-beam/X-Ray), presented within the FAO and IAEA Atoms4Food Initiative, ensures product safety and reduces the cost of purchasing additional food volumes.

E-Beamcomplex manufactures container-type boxes (E-Beambox) that can be quickly installed and put into operation in long-term storage warehouses for the phytosanitary treatment of food products with ionizing radiation to ensure extended shelf life and reduced losses

E-beambox allows for the processing of various food products, such as flour, cereals, pulses, LNS (lipid-based nutrient supplements), frozen meat, and other products.

Using X-Ray and E-beam food products may be processed in any type of packaging: in boxes, bags, and on pallets.

Processed product temperature ranges from -18°C to 40°C.

While treatment all pathogenic microorganisms and parasites are destroyed without compromising product quality, ensuring no recontamination, preserving all nutritional properties and extending food shelf life.

IONIZING RADIATION FOOD TREATMENT TECHNOLOGY

Electron accelerators generating ionizing radiation (E-beam and X-Ray) have been used for more than 60 years for phytosanitary food processing.

E-beam/X-rays pierce through the product and effectively destroy pathogenic microorganisms and parasites, thereby increasing the shelf life of the products.

Types of products supplied as part of humanitarian aid that are subject to treatment with ionizing radiation:

* Products are packaged in polymer oxygen-barrier bags.

SHELF LIFE OF PRODUCTS TREATED WITH IONIZING RADIATION

The shelf life of processed products depends on the following factors:

- The level of contamination of food products with pathogens, insects and their larvae before the process of ionizing radiation treatment.

- The characteristics of the packaging material (materials and packages that prevent the ingress of insects and pathogenic microorganisms, as well as materials with an oxygen barrier provide the longest shelf life).

- The level of sterility of the storage facilities in which the products will be stored after their radiation treatment.

- Temperature conditions and humidity in the storage facilities.

*The long shelf life is due to the fact that the products are exposed to the maximum permissible dose of radiation, as well as the use of packaging materials that are insect-, moisture- and oxygen-proof.

| Types of Food Products | Irradiation Dose (kGy) | Mode | Shelf Life Extension |

|---|---|---|---|

| 1) Instant porridges | 1 | E-beam/X-Ray | Up to to 5 years, *Up to 10 years |

| 2) Cereals (rice, semolina, buckwheat, etc.) | 1 | E-beam/X-Ray | Up to to 5 years, *Up to 10 years |

| 3) Flour | 4 | E-beam/X-Ray | Up to to 5 years, *Up to 10 years |

| 4) Noodle products | 4 | E-beam/X-Ray | Up to to 5 years, *Up to 10 years |

| 5) Liophilized beef powder | 7 | E-beam/X-Ray | Up to to 5 years, *Up to 10 years |

| 6) Frozen chicken meat, poultry | 7 | E-beam/X-Ray | Up to 1 year, *Up to 3 years |

| 7) Frozen beef | 7 | E-beam/X-Ray | Up to 1 year, *Up to 3 years |

| 8) Casein, caseinates | 6 | E-beam/X-Ray | Up to 1 year, *Up to 10 years |

| 9) Tea, coffee, cocoa | 1-14 | E-beam/X-Ray | Up to 3 years, *Up to 10 years |