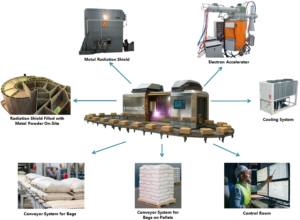

Beamcomplex manufactures 40-ft boxes with electron accelerators – E-Beambox – for placement in long-term storage food warehouses to treat food products with ionizing radiation.

The boxes come in two models:

| Model | Purpose of Use | Mode | Power | Energy |

| C5.50EXRK12 | Treat products in boxes/bags | E-beam/X-Ray | 50 kW | 5 MeV |

| C5.100EXRK12 | Treat products in boxes/bags on pallets | X-Ray | 100 kW | 5 MeV |

E-beambox contents

E-Beambox is designed to treat food products:

1) Imported into warehouses. | 2) Stored in warehouses. | 3) Exported from warehouses.

Advantages of E-Beambox

Operation of the box requires only a site and access to electricity; no facility remodeling is required

The box's conveyor system can be integrated into an existing production line for convenient operation

E-Beambox is a prefabricated container-type system, ready for quick installation and commissioning - installation process takes three months

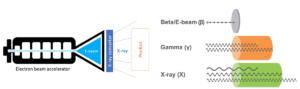

IONIZING RADIATION TREATMENT TECHNOLOGY

E-beam (Electron Beam) — High-speed electrons → Precise, powerful processing

• An E-beam is a stream of fast-moving electrons.

• Electrons are very light and charged, so they can be accelerated easily.

• When accelerated, they form a high-energy beam that can treat and modify materials.

X-Ray — High-energy photons → Deep penetration through materials

• X-rays are high-energy electromagnetic waves.

• Their photons have enough energy to ionize atoms and break molecular bonds.

• This makes X-rays an effective form of ionizing radiation for product treatment.

Advantages of Ionizing Radiation Treatment Technology

Effectively treats various food products, such as flour, cereals, pulses, LNS (lipid-based nutrient supplements), frozen meat, and other products

Eliminates pathogenic microorganisms (e.g. Salmonella, E. coli) thus extending product shelf life

The temperature of products to be treated ranges from -18°C to 40°C

Food products may be processed in any type of packaging: in boxes, bags, and on pallets

Leaves no residual radiation — the product remains completely safe

Preserves the natural structure and organoleptic properties of food

Advantages of Having E-Beambox in Food warehouse

Reduction of food losses and waste due to the extended food shelf life

Complete independence from companies providing treatment services

Complete quality control – all processes are carried out under your supervision

SHELF LIFE OF PRODUCTS TREATED WITH IONIZING RADIATION

The shelf life of processed products depends on the following factors:

1) The level of contamination of food products with pathogens, insects and their larvae before the process of ionizing radiation treatment.

2) The characteristics of the packaging material (materials and packages that prevent the ingress of insects and pathogenic microorganisms, as well as materials with an oxygen barrier provide the longest shelf life).

3) The level of sterility of the storage facilities in which the products will be stored after their radiation treatment.

4) Temperature conditions and humidity in the storage facilities.

*The long shelf life is due to the fact that the products are exposed to the maximum permissible dose of radiation, as well as the use of packaging materials that are insect-, moisture- and oxygen-proof.

| Types of Food Products | Irradiation Dose (kGy) | Mode | Shelf Life Extension |

|---|---|---|---|

| 1) Instant porridges | 1 | E-beam/X-Ray | Up to to 5 years, *Up to 10 years |

| 2) Cereals (rice, semolina, buckwheat, etc.) | 1 | E-beam/X-Ray | Up to to 5 years, *Up to 10 years |

| 3) Flour | 4 | E-beam/X-Ray | Up to to 5 years, *Up to 10 years |

| 4) Noodle products | 4 | E-beam/X-Ray | Up to to 5 years, *Up to 10 years |

| 5) Liophilized beef powder | 7 | E-beam/X-Ray | Up to to 5 years, *Up to 10 years |

| 6) Frozen chicken meat, poultry | 7 | E-beam/X-Ray | Up to 1 year, *Up to 3 years |

| 7) Frozen beef | 7 | E-beam/X-Ray | Up to 1 year, *Up to 3 years |

| 8) Casein, caseinates | 6 | E-beam/X-Ray | Up to 1 year, *Up to 10 years |

| 9) Tea, coffee, cocoa | 1-14 | E-beam/X-Ray | Up to 3 years, *Up to 10 years |