COLD STERILIZATION WITH ACCELERATED ELECTRONS KILLS PATHOGENS AND INCREASES THE SHELF LIFE OF THE PRODUCTS TO BE PROCESSED!

Presentation of Fruit Irradiation Technology

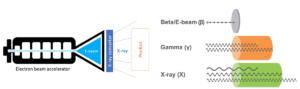

IONIZING RADIATION TREATMENT TECHNOLOGY

E-BEAMBOX generates E-beam and X-Ray that penetrate various substances, materials and products. The electron beam technology is used for sterilization purposes of food products.

E-beam (Electron Beam) — High-speed electrons → Precise, powerful processing

E-beam (Electron Beam) — High-speed electrons → Precise, powerful processing

• An E-beam is a stream of fast-moving electrons.

• Electrons are very light and charged, so they can be accelerated easily.

• When accelerated, they form a high-energy beam that can treat and modify materials.

X-Ray — High-energy photons → Deep penetration through materials

• X-rays are high-energy electromagnetic waves.

• Their photons have enough energy to ionize atoms and break molecular bonds.

• This makes X-rays an effective form of ionizing radiation for product treatment.

Approved by FDA & USDA

The U.S. FDA officially permits the use of ionizing radiation for fresh fruits to ensure phytosanitary safety and extend shelf life. FDA regulations authorize doses up to:

≤ 1.0 kGy — fresh fruits and vegetables (phytosanitary treatment, insect disinfestation, delay of ripening)

According to the FDA, irradiation:

– reduces pathogens such as Salmonella and E. coli

– prevents spoilage

– extends shelf life

– does not make food radioactive

– does not significantly affect nutritional quality, taste, texture, or appearance

U.S. Code of Federal Regulations 21 CFR Part 179 (Dec. 1, 2005)

Backed by IAEA, FAO and WHO

“Food irradiated up to an overall average dose of 10 kGy presents no toxicological hazard; nutritional and microbiological adequacy are maintained.” — WHO, 1994

“Irradiation can reduce the risk of food poisoning, control food spoilage and extend the shelf-life of foods without detriment to health… This view has been endorsed by… WHO, FAO and Codex Alimentarius.” — IAEA/FAO, 2016

In 2025, the IAEA continues to endorse food irradiation as a safe and effective technology. “Irradiated food does not become radioactive. The process is safe and the food remains wholesome and nutritious.” — IAEA, 2025

Validated by Recent Studies

Backed by 30+ years of research, food irradiation is recognized as safe and effective by leading global authorities, including WHO, IAEA, FAO, FDA, and USDA, as well as by the international scientific community.

Scientific evidence shows:

• E-beam irradiation up to 1 kGy can be used for fruits without significant changes in physicochemical and sensory quality.

• Papaya treated at 1 kGy showed quality parameters comparable to control.

• Mango fruit tolerated E-beam doses up to 0.5 kGy without peel injury.

• E-beam treatment at 0.4–0.6 kGy effectively extended the shelf life of star apple fruits without affecting color or weight loss.

The science is clear — and the latest studies confirm it: irradiation works, safely and effectively

Cooperation Options

Beamcomplex offers three cooperation options:

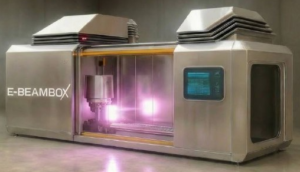

1) Turnkey E-Beambox Installation by Beamcomplex

Beamcomplex independently provides the installation of the box with an electron accelerator and assigns its own specialists to perform all commissioning and start-up works.

2) Contract irradiation services

Provision of ionizing radiation treatment services for food products at the multifunctional Radiation Processing Center using the box.

3) Supply and on-site installation of E-Beambox at the partner’s facility

Sale, installation, and commissioning of E-Beambox directly at fruit processing plants, and other industrial facilities.

Advantages of E-Beambox:

| Operation of the box requires only a site and access to a power supply; no facility remodeling is required. |

| The box’s conveyor system can be integrated into an existing production line for convenient operation |

| E-Beambox is a prefabricated container-type system, ready for quick installation and commissioning. |

| Installation and commissioning of the box eliminates interruptions and delays in the production process |

Technical Characteristics of the E-BeamBox

E-BEAMBOX includes:

• Electron accelerator (of various power/energy)

• Special equipment (conveyor systems, radiation monitoring systems, etc.)

• Radiation shield (filled with concrete on-site)

Minimum installation area — 12 x 2.5 m

Models C5.100EXRK12 / C5.50EXRK12

• Designed for processing products in bulk, bags, boxes or on pallets.

• Equipped with two conveyor lines: for boxes/bags and for palletized loads.

E-Beambox Placement Options

In the finished goods workshop – to process packaged products before shipment – a fully integrated system without changing the production cycle.

Technical Parameters

- Dose: 3 kGy

- Power: 100 kW

- Throughput: up to 6 t/h (X-Ray, product > 50 mm)

Main advantage of E-Beambox: may be installed in existing facilities with limited space.

In the production workshop, after packaging, with direct connection to the existing conveyor line – a fully integrated system without changing the production cycle.

Technical Parameters

- Dose: 3 kGy

- Power: 100 kW

- Throughput: up to 120 t/h (E-beam/X-Ray, product < 50 mm)

Main advantage of E-Beambox: may be installed in existing facilities with limited space.

Ways of Product Processing

Advantages of Installing E-Beambox Directly On Site

Stronger brand trust – advanced on-site technology clearly demonstrates a high level of safety and reliability to consumers

Faster time-to-market – eliminating external logistics significantly speeds up product release

Maximum flexibility – treatment of any product format: individual packs, boxes, or full pallets

Full quality control – all processing is performed under your own supervision, with no reliance on external service providers

Advantages of Receiving Processing Services at the Center

Logistics convenience – the center may be located near major fruit producers, logistics centers, sea and river ports, and other key facilities

100% safety guarantee – processing using electron accelerators with the energy of up to 10 MeV is a completely safe process that leaves no residual radiation in products

Quality guarantee according to international standards – each batch of processed products receives a certificate that meets international standards

Volume-based pricing – the cost per unit of processing decreases as the volume of products to be processed increases

Two-stage quality control – laboratory testing of products both before processing (to determine the optimal irradiation dose based on the microbial load) and after (to confirm complete destruction of pathogens)

Advantages of Processing Seafood with Ionizing Radiation

Preserves the natural structure and organoleptic properties of fruits

Increases consumer confidence through guaranteed quality and safety

Leaves no residual radiation — the product remains completely safe

The temperature of processed products may vary from 0°C to 30°C

Eliminates insects and reduces pathogenic microorganisms, including Salmonella and E. coli

Allows processing in any sealed packaging, preventing recontamination

Environmentally friendly and energy-efficient treatment method

Slowed ripening

IRRADIATION OF FRUIT AND BERRIES

| Treatment mode | Power | Dose | Thickness of treated product | Throughput |

|---|---|---|---|---|

| X-Ray | 50 kW | 250 Gy | Up to 1200 mm | 36 MT/hour |

| X-Ray | 100 kW | 250 Gy | Up to 1200 mm | 72 MT/hour |

Scientific Reports

Fruits and Vegetables

Irradiation as a phytosanitary treatment of food and agricultural commodities (IAEA). 2002

MoreIrradiation of fruits and vegetables

Impact of irradiation on physico-chemical nutrition properties of fruits and vegetables: a mini review. 2022

MoreAre you currently interested in phytosanitary treatment of fruit and berries to destroy pathogens and eliminate insects?

If YES, please press the button and we will answer all your questions:

We are ready to implement the technology and need more information