COLD STERILIZATION WITH ACCELERATED ELECTRONS KILLS INSECTS AND INCREASES THE SHELF LIFE OF THE PRODUCTS TO BE PROCESSED!

Beamcomplex offers complexes to treat rice with ionizing radiation to commercial enterprises to ensure elimination of insects and their larvae, reduction in the number of pathogenic microogranisms and extension of shelf life of the treated product. Having such complexes you will have a competitive advantage, differentiate your product and retain leading positions in the local and global rice markets.

BEAMCOMPLEX EQUIPMENT FOR RICE IRRADIATION

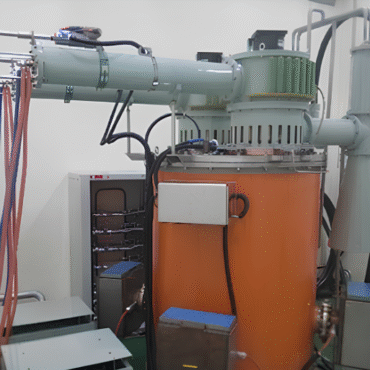

Beamcomplex manufactures compact container-type complexes with electron accelerators operating in E-beam and X-Ray modes with the energy of 5 MeV and a power of 50 kW and 100 kW for rice irradiation.

The complexes allow treatment in sealed packaging without compromising product quality, ensuring no recontamination and preserving all nutritional properties.

Beamcomplex manufactures 3 types of rice treatment complexes:

1) Beamcomplex С5.50E8 is designed for treating rice with accelerated electrons in one layer for further filling it into bags.

2) Beamcomplex С5.50P10 and Beamcomplex C5.100P11 are designed for treating rice with ionizing radiation in two modes — E-beam and X-Ray. In this complex, rice is treated in packaged form in bags and also in bags on pallets.

The equipment integrates seamlessly into any production process without requiring a plant shutdown, allowing it to be installed at any operating facility.

During installation, the complex’s conveyor is connected with the customer’s conveyor system. It is possible to treat rice both vertically and horizontally due to the dual window outlet device.

Besides Beamcomplex specializes in the construction of a full-scale phytosanitary treatment center equipped with multiple complexes with electron accelerators, strategically located near rice production facilities, where Beamcomplex can render phytosanitary treatment services.

X-Ray treatment of packed rice

X-Ray treatment of packed rice Electron accelerator that generates E-beam/X-Ray

Electron accelerator that generates E-beam/X-Ray Irradiated rice stored at food warehouse for 10 years

Irradiated rice stored at food warehouse for 10 yearsIONIZING RADIATION TECHNOLOGY FOR RICE TREATMENT

E-beam/X-Ray, generated by an electron accelerator, penetrate the product and effectively eliminate insects and their larvae and reduce the number of pathogenic microorganisms to required limits by inducing breaks in their DNA, thus extending product’s shelf life.

BENEFITS OF USING A COMPLEX WITH THE TECHNOLOGY OF TREATING RICE WITH IONIZING RADIATION

The technology allows the use of oxygen-tight packaging that eliminates the risk of rice contamination after irradiation.

High processing speed.

Unique technology that guarantees shelf life extension of rice up to 10 years.

Organoleptic properties of rice are preserved.

The essential nutrients (amino acids, fats, vitamins) of rice remain intact after irradiation.

No residual radiation in irradiated rice.

PROCESSING OPTIONS

- E-beam is used to irradiate rice in bulk prior to packaging.

- X-ray is used to irradiate rice bags up to 50 kg with rice packed in small/medium plastic packages.

- X-ray is used to irradiate rice bags on pallets and rice bulk bags up to 2 mt.

THROUGHPUT OF THE COMPLEXES

! The capacity depends on a radiation dose. The dose value is selected taking into account the level of infestation and resistance of certain insect pest species to radiation.

| Model | Treatment mode | Power consumption of complex per hour, kW | Rice throughput, t/h |

|---|---|---|---|

| Beamcomplex С5.50E8 | E-beam | 160 | 180 |

| Beamcomplex С5.50P10 | X-Ray/E-beam | 160 | 9 |

| Beamcomplex С5.100P11 | X-Ray/E-beam | 210 | 18 |

SHELF LIFE OF RICE TREATED WITH IONIZING RADIATION

An important factor in ensuring long shelf life is to process the packed rice as early as possible. The earlier the packaged product is sterilized, the earlier the insect pest reproduction process stops, thereby reducing the risk of insect waste contaminating the rice and thereby extending rice shelf life.

Besides the shelf life of processed products depends on the following factors:

- The level of contamination of food products with pathogens, insects and their larvae before the process of ionizing radiation treatment.

- The characteristics of the packaging material (materials with an oxygen barrier provide the longest shelf life).

- The level of sterility of the storage facilities in which the products will be stored after their radiation treatment.

- Temperature conditions and humidity in the storage facilities.

Rice shelf life extension: in insect-proof packaging — 5 years, in oxygen- and water-proof packaging — 7 years, in oxygen- and water-proof bags vacuumized with inert gas — 10+ years.

Scientific Reports

Thailand Institute of Nuclear Technology

Increasing γ-Aminobutyric Acid in Mixed Germinated Brown Rice Via Electron Beam Irradiation. 2024

MoreJiangnan University, Key Laboratory of Carbohydrate Chemistry and Biotechnology

Influence of Electron Beam Irradiation on the Moisture and Properties of Freshly Harvested and Sun-Dried Rice. 2020

MoreAre you currently interested in phytosanitary treatment of rice to extend its shelf life?

If YES, please press the button and we will answer all your questions:

We are ready to implement the technology and need more information