COLD STERILIZATION WITH ACCELERATED ELECTRONS KILLS PATHOGENS AND INCREASES THE SHELF LIFE OF THE PRODUCTS TO BE PROCESSED!

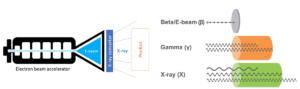

IONIZING RADIATION TREATMENT TECHNOLOGY

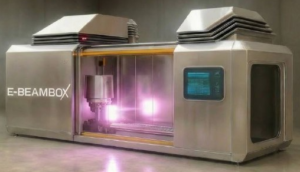

E-BEAMBOX generates E-beam and X-Ray that penetrate various substances, materials and products. The electron beam technology is used for sterilization purposes of food products.

E-beam (Electron Beam) — High-speed electrons → Precise, powerful processing

E-beam (Electron Beam) — High-speed electrons → Precise, powerful processing

• An E-beam is a stream of fast-moving electrons.

• Electrons are very light and charged, so they can be accelerated easily.

• When accelerated, they form a high-energy beam that can treat and modify materials.

X-Ray — High-energy photons → Deep penetration through materials

• X-rays are high-energy electromagnetic waves.

• Their photons have enough energy to ionize atoms and break molecular bonds.

• This makes X-rays an effective form of ionizing radiation for product treatment.

Approved by FDA & USDA

The U.S. FDA officially permits the use of ionizing radiation for seafood such as lobster, shrimp, crab, oysters, clams, mussels, and scallops. FDA regulations authorize doses up to:

– 5.5 kGy for oysters, clams, mussels, and scallops

– 6.0 kGy for lobster, shrimp, and crab

According to the FDA, irradiation:

– reduces pathogens such as Salmonella and E. coli

– prevents spoilage

– extends shelf life

– does not make food radioactive

– does not significantly affect nutritional quality, taste, texture, or appearance

U.S. Code of Federal Regulations 21 CFR Part 179 (Dec. 1, 2005)

Backed by IAEA, FAO and WHO

Tuna (Thunnus obesus)

“At 2.2 kGy, shelf-life increased from 15 days (control) to 25 days for frozen loins, with oxidative rancidity delayed.” — IAEA, 2000

Shrimp — Tropical

“Optimum dose for raw shrimp: 1.5-2.0 kGy, shelf-life ~42 days at 3°C. A dose of 4.0-5.0 kGy could be used to eliminate Salmonella, Vibrio, etc. from fresh or frozen blocks of seafood.” — IAEA, 2000

Squid / Cuttlefish

”For dried cuttlefish: 3.0 kGy eliminated all pathogens and molds. For roasted dried cuttlefish: 2.0 kGy was effective. Shelf-life depended on moisture: >9 months if moisture <19%.” — IAEA, 2000

“Irradiation can reduce the risk of food poisoning, control food spoilage and extend the shelf-life of foods without detriment to health… This view has been endorsed by… WHO, FAO and Codex Alimentarius.”— IAEA/FAO, 2016

“Food irradiated up to an overall average dose of 10 kGy presents no toxicological hazard; nutritional and microbiological adequacy are maintained.” — WHO, 1994

Validated by Recent Studies

Backed by 30+ years of research, food irradiation is recognized as safe and effective by leading global authorities, including WHO, IAEA, FAO, FDA, and USDA, as well as by the international scientific community.

Scientific evidence shows (2023-2025):

• Fish products: Studies report that irradiated fish maintained good to very good sensory quality, and all chemical parameters remained within acceptable limits.

• Squid: Vacuum-packed squid rings treated with 1.8–5.8 kGy showed a shelf-life increase from 3 to 27 days at 4 kGy, while keeping high sensory acceptability.

• Shrimp: Low-dose irradiation caused no significant changes in protein, fat, carbohydrates, or amino acids; nutritional and sensory quality remained stable, with effects comparable to cooking or chilled storage.

The science is clear — and the latest studies confirm it: irradiation works, safely and effectively.

Antibiotic Reduction in Seafood

“…Radiation is very efficient for destroying the residual antibiotics (e.g. flumequine) in seafood or food in general. Chloramphenicol is degraded by 50.61%, however, if irradiation time and exposure doses are increased, chloramphenicol will be eliminated more and more. Additionally, while gamma radiation is being emitted on seafood, the residual antibiotics will degrade and will be affected by both gamma radiation and the enzyme of living creatures.”

Cooperation Options

Beamcomplex offers three cooperation options:

1) Turnkey E-Beambox Installation by Beamcomplex

Beamcomplex independently provides the installation of the box with an electron accelerator and assigns its own specialists to perform all commissioning and start-up works.

2) Contract irradiation services

Provision of ionizing radiation treatment services for food products at the multifunctional Radiation Processing Center using the box.

3) Supply and on-site installation of E-Beambox at the partner’s facility

Sale, installation, and commissioning of E-Beambox directly at poultry processing plants, and other industrial facilities.

QUICK INSTALLATION AND QUICK START-UP ON CUSTOMER’S SITE!

Advantages of E-Beambox:

| Operation of the box requires only a site and access to a power supply; no facility remodeling is required. |

| The box’s conveyor system can be integrated into an existing production line for convenient operation |

| E-Beambox is a prefabricated container-type system, ready for quick installation and commissioning. |

| Installation and commissioning of the box eliminates interruptions and delays in the production process |

Technical Characteristics of the E-BeamBox

E-BEAMBOX includes:

• Electron accelerator (of various power/energy)

• Special equipment (conveyor systems, radiation monitoring systems, etc.)

• Radiation shield (filled with concrete on-site)

Minimum installation area — 12 x 2.5 m

Models C5.100EXRK12 / C5.50EXRK12

• Designed for processing products in bulk, bags, boxes or on pallets.

• Equipped with two conveyor lines: for boxes/bags and for palletized loads.

E-Beambox Placement Options

In the finished goods workshop – to process packaged products before shipment – a fully integrated system without changing the production cycle.

Technical Parameters

- Dose: 3 kGy

- Power: 100 kW

- Throughput: up to 6 t/h (X-Ray, product > 50 mm)

Main advantage of E-Beambox: may be installed in existing facilities with limited space.

In the production workshop, after packaging, with direct connection to the existing conveyor line – a fully integrated system without changing the production cycle.

Technical Parameters

- Dose: 3 kGy

- Power: 100 kW

- Throughput: up to 120 t/h (E-beam/X-Ray, product < 50 mm)

Main advantage of E-Beambox: may be installed in existing facilities with limited space.

Ways of Product Processing

Advantages of Installing E-Beambox Directly On Site

Stronger brand trust – advanced on-site technology clearly demonstrates a high level of safety and reliability to consumers

Faster time-to-market – eliminating external logistics significantly speeds up product release

Maximum flexibility – treatment of any product format: individual packs, boxes, or full pallets

Full quality control – all processing is performed under your own supervision, with no reliance on external service providers

Key Advantages of Receiving Processing Services at the Center

Logistics convenience – the center may be located near major seafood producers, logistics centers, sea and river ports, and other key facilities

100% safety guarantee – processing using electron accelerators with the energy of up to 10 MeV is a completely safe process that leaves no residual radiation in products

Quality guarantee according to international standards – each batch of processed products receives a certificate that meets international standards

Volume-based pricing – the cost per unit of processing decreases as the volume of products to be processed increases

Two-stage quality control – laboratory testing of products both before processing (to determine the optimal irradiation dose based on the microbial load) and after (to confirm complete destruction of pathogens)

Advantages of Processing Seafood with Ionizing Radiation

Complete destruction of pathogenic microorganisms, including Salmonella and E. coli, and a reduction in antibiotic and hormonal content in the product

Can be processed in any sealed packaging, preventing product recontamination

Product temperatures range from -32°C to +4°C. The product temperature remains unchanged during processing

The structure of proteins, fats, and amino acids is not disrupted, leaving organoleptic properties unchanged

After processing, there is no residual radiation in the product, making it completely safe and ready to eat

Radiation processing is an environmentally friendly process

Strengthening consumer confidence in the product through its guaranteed quality and safety

After processing, the product's shelf life is extended, allowing for loss-free sale of the finished product

Examples of Treated Products

ANTIBACTERIAL TREATMENT OF SEAFOOD WITH E-BEAM AND X-RAY RADIATION TO DESTROY PATHOGENIC MICROORGANISMS (SALMONELLA, HELMINTHS, ETC.)

Phytosanitary Treatment of Pet and Fish Feed Using Ionizing Radiation

Benefits of Pet and Fish Food Irradiation Using Boxes with Electron Accelerators

Destruction of pathogens to improve product safety and reduce production losses

Extended shelf life of treated products

Sterilizes hermetically sealed fish food, preventing recontamination and ensuring quality throughout its shelf life

No residual radiation and free radicals in the treated products

Retains fish food's organoleptic properties for the entire shelf life

High processing speed

Waste-free production, since fish feed is made of seafood by-products

IRRADIATION OF SHRIMPS/PRAWNS

| Treatment mode | Dose | Power | Thickness of treated product | Throughput |

|---|---|---|---|---|

| E-beam: Shrimp treatment in bulk without flipping, followed by packaging into sealed polymer bags. The bags are sterilized prior to packaging | 3 kGy | 100 kW | Up to 25 mm | 120 MT/hour |

| E-beam: Shrimp treatment in sealed polyethylene packaging with flipping: passed twice under the E-beam | 3 kGy | 100 kW | Up to 50 mm | 120 MT/hour |

| X-Ray: Shrimp treatment in boxes and on pallets (sealed packaging) | 3 kGy | 100 kW | Up to 1200 mm | 6 MT/hour |

Are you currently interested in shrimp/prawn treatment to destroy pathogens and extend product shelf life?

If YES, please press the button and we will answer all your questions:

We are ready to implement the technology and need more information