E-BEAMBOX generates E-beam and X-Ray that penetrate various substances, materials and products. The electron beam technology is used for sterilization purposes and improvement of material properties.

X-Ray/E-beam

An E-beam (i.e. electron beam) consists of a stream of electrons accelerated to high speeds.

An E-beam (i.e. electron beam) consists of a stream of electrons accelerated to high speeds.

They carry a negative charge and have a small mass, allowing them to accelerate rapidly under electric fields. This acceleration results in high-energy beams capable of performing intricate tasks in technology and research.

An X-Ray (i.e. Röntgen radiation) is a form of high-energy electromagnetic radiation with photons that carry enough energy to ionize atoms and disrupt molecular bonds. This makes it a type of ionizing radiation, impacting living and non-living tissues.

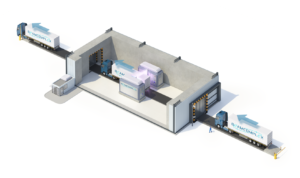

The E-BEAMBOX can be simultaneously equipped with 2 to 3 conveyor systems to irradiate products in boxes, in bulk in one layer, on pallets, in bags and in cargo containers.

IAEA ON IONIZING RADIATION SAFETY

Food product treatment to maximize their shelf life

Operating principle of food irradiation technology: the electron accelerator uses high energy electrons and X-rays, penetrates through the product, causes DNA rupture of pathogens, harmful bacteria, mold, fungi, insect pests, their larvae, thereby destroying them. This is the only food safety technology that allows processing products in sealed packaging.

The combination of oxygen-barrier packaging, inert gas, vacuumizing, high-dose irradiation, and proper storage conditions for the processed product (acceptable level of storage sterility, temperature and humidity conditions) maximizes its shelf life.

For example, the shelf life of rice processed in insect-proof packaging is 5 years, in oxygen- and water-proof packaging — 7 years, in oxygen- and water-proof bags vacuumized with inert gas — 10+ years.

ADVANTAGES

- Reduction or complete destruction of pathogenic microorganisms

- Elimination of re-contamination, since the products are processed in sealed packaging

- Maximized shelf life

- Preservation of the cellular and molecular structure, micro- and macroelements (vitamins, proteins, fats, amino acids), and minerals in food products

- Retention of the original structure of both packaging and products

- Absence of residual radiation in processed products

PHYTOSANITARY TREATMENT OF FOOD PRODUCTS

Products are transported in packages or open containers via a conveyor belt into a chamber where they are processed with an accelerated electron beam.

Products are transported in packages or open containers via a conveyor belt into a chamber where they are processed with an accelerated electron beam.

- If necessary, the packaging is turned over to ensure uniform processing.

- Processing time varies from several seconds to several minutes.

- Temperature control is maintained during processing.

- The absorption of electron energy results in damage to DNA and RNA, leading to the destruction of insects and pathogenic microorganisms.

ADVANTAGES

- Microbial suppression (fresh raw materials, meat, poultry, fish and semi-finished products).

- Destruction of insects and their larvae, pathogens, and also reduction of the content of mycotoxins (grains, cereals, dried fruits and vegetables, dried fish and meat of all types).

- Extended shelf life (berries, fruits, vegetables, meat, poultry, fish, mushrooms).

- Decontamination of additives and ingredients (spices, animal feed, enzyme preparations).

- Preservation of the cellular, molecular structure, micro-, macroelements (vitamins, proteins, fats, amino acids) and minerals of food products.

- Slowing down the ripening process (fresh fruits and vegetables).

- Sprouting inhibition (potatoes, onions, root vegetables, etc.).

- Reduction of residual levels of antibiotics and hormones.

- No residual radiation in processed products.

STERILE INSECT TECHNIQUE

Mass-rearing of insects takes place in special facilities. Male and female insects are separated. Ionizing radiation is used to sterilize male insects. The sterile male insects are released over towns or cities to mate with females. these females lay eggs that are infertile and bear no offspring, reducing the insect population.

Mass-rearing of insects takes place in special facilities. Male and female insects are separated. Ionizing radiation is used to sterilize male insects. The sterile male insects are released over towns or cities to mate with females. these females lay eggs that are infertile and bear no offspring, reducing the insect population.

ADVANTAGES

- A significant reduction in crop and livestock production losses;

- Protection of the horticultural and livestock industries through prevention of pest introductions;

- Providing conditions for commodity exports to high value markets without quarantine restrictions;

- Protecting and creating jobs;

- Significant reduction in production and human health costs;

- Environmental protection through a reduced use of insecticides.

STERILIZATION OF MEDICAL DEVICES, FOOD PACKAGING, COSMETICS, ETC.

Electron accelerators use high energy electrons and X-rays as a sterilization method. The electron accelerator generates and accelerates electrons

that pass through materials and products, causing breaks in the DNA of pathogens, thus sterilizing the materials. Products can be processed in tightly sealed packaging, preventing recontamination.

ADVANTAGES

- Complete destruction of pathogens, viruses and bacteria.

- The only method of sterilization in individual packaging that prevents recontamination.

- The fastest sterilization method, many times faster than sterilization with Co-60 or ethylene oxide.

- Complete sterility of products and both internal and external surfaces of the packages.

- The treatment does not affect the physical and chemical properties of the package.

- No residual radiation in processed products.

CARGO CONTAINER PROCESSING

Electron accelerators generate X-rays that penetrate the walls of a closed container and induce breaks in DNA of insects and their larvae, eliminating them, as well as pathogens, significantly reducing them in number.

ADVANTAGES

- No need to open containers and take the products out for treatment.

- High sterilization rate.

- 100% guarantee of insect pest and their larvae destruction, and significant reduction in the number of pathogens in transported products.

We are ready to answer all your questions!