Beamcomplex manufactures compact complexes with electron accelerators for food packaging sterilization. Such complexes have been designed for installation in food production plants to sterilize product packagings. Please refer to Packaging for Food Irradiation (IAEA).

BEAMCOMPLEX EQUIPMENT FOR FOOD PACKAGING STERILIZATION

BEAMCOMPLEX EQUIPMENT FOR FOOD PACKAGING STERILIZATION

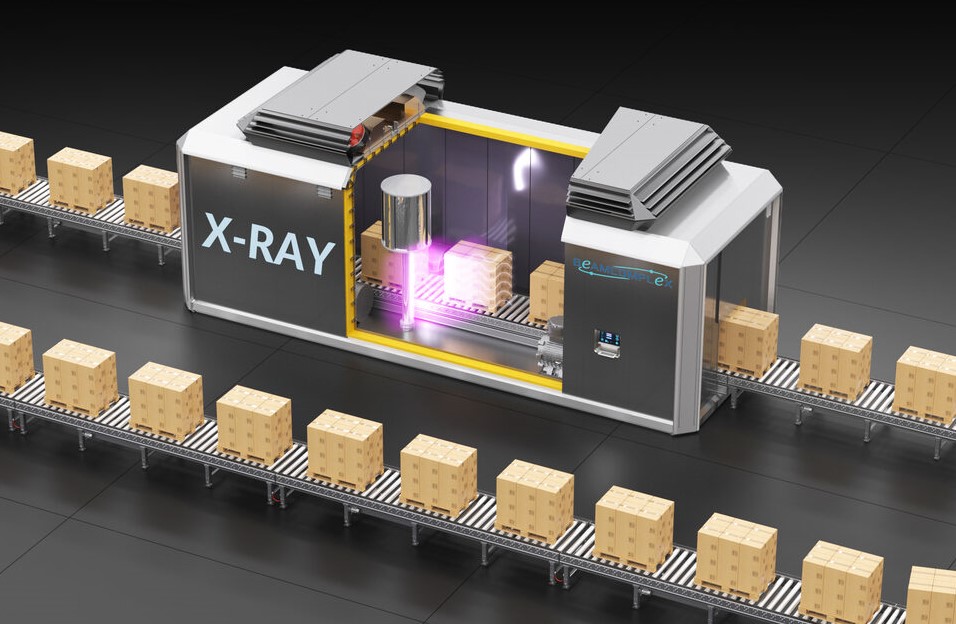

Our company specializes in the production of complexes with electron accelerators for food packaging sterilization with ionizing radiation (E-beam and X-Ray).

Due to the fact that our equipment is seamlessly integrated into any technological process, it can also be installed at any operating facilities.

During installation, the complex’s conveyor is connected with a customer’s conveyor system. The complex is installed without plant shutdown.

IONIZING RADIATION TECHNOLOGY FOR FOOD PACKAGING STERILIZATION

Electron accelerators use high energy of electrons and X-Ray as a method of sterilization. Electron accelerators generate and accelerate electrons that penetrate the product and sterilize all internal and external surfaces of food packagings.

E-beam and X-Ray treatment of materials and products is environmentally friendly technology as it uses only electricity.

The time period when a product is exposed to radiation impacts the radiation dose value: the longer the product stays under X-Ray or E-beam, the higher the dose. For dose uniformity, the product needs to be turned. In case of treatment in pallets, the pallet rotates around its axis under the electron beam outlet window.

WHAT FOOD PACKAGINGS DO WE STERILIZE USING COMPLEXES WITH ELECTRON ACCELERATORS?

Food pouches

Food pouches Other food containers to store products in liquid, bulk or solid state

Other food containers to store products in liquid, bulk or solid state *photo credit from Scholle IPN

*photo credit from Scholle IPNBENEFITS OF FOOD PACKAGING STERILIZATION USING COMPLEXES WITH ELECTRON ACCELERATORS

Complete sterility of both internal and external surfaces of the packaging.

The material structure doesn't change. The treatment doesn't affect physical or chemical properties of packaging material.

Sterilization by electron accelerators guarantees safe use and filling of the sterilized packaging and eliminates recontamination.

No residual radiation in irradiated products.